Our new paper in Frontiers Bioeng. Biotechnol.: Bioactive glass-PLA 3D scaffold manufacturing by fused deposition modeling

In this study [1], we showed the fabrication of composite polylactic acid-bioactive glass (PLA-BG) (3D printing) filaments to 3D print open porous, bioactive and osteoinductive scaffolds for bone and osteochondral tissue engineering via fused deposition modeling (FDM). This research was conducted in the framework of the Collaborative Research Centre (CRC/SFB) 1270 “ELAINE” – Electrically Active Implants with the group of Prof. Hermann Seitz at Chair of Mikrofluidics, University of Rostock. In vitro cytocompatibility and gene expression studies confirmed osteoinductive properties of the scaffolds achieved by BG addition, highlighting the potential of the engineered composite materials for bone engineering applications.

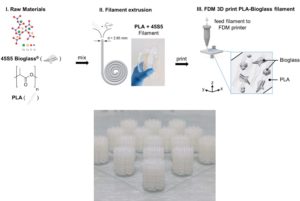

*Figure:* Schematic of PLA-45S5 BG composite filament preparation for FDM. (Adapted from T. Distler, et al., Front. Bioeng. Biotechnol. 8 (2020) 552. Published under the terms of the Creative Commons Attribution License (CC BY) <http://creativecommons.org/licenses/by/4.0/>).

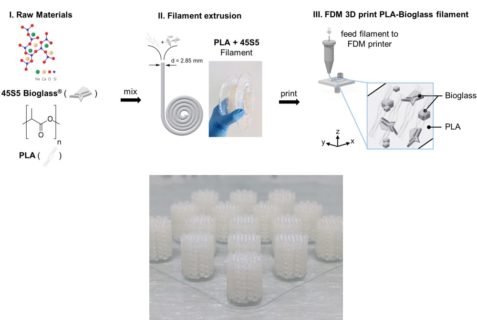

*Figure*: 3D Printed PLA-BG scaffolds via FDM. (Adapted from T. Distler, et al., Front. Bioeng. Biotechnol. 8 (2020) 552.Published un der the terms of the Creative Commons Attribution License (CC BY) <http://creativecommons.org/licenses/by/4.0/>).

[1] T. Distler, et al., Polymer-Bioactive Glass Composite Filaments for 3D Scaffold Manufacturing by Fused Deposition Modeling: Fabrication and Characterization, Front. Bioeng. Biotechnol. 8 (2020) 552.